008615129504491

1.Brief introduction

| Grade | Gr5, Ti-6Al-4V ELI |

| Standard | ISO5832-3, ASTM F136 |

| Diameter | 1-4mm |

| Tensile strength | >1080MPa |

| Shape | Straight wire |

| Characteristic | Surface roughness≤0.8µm |

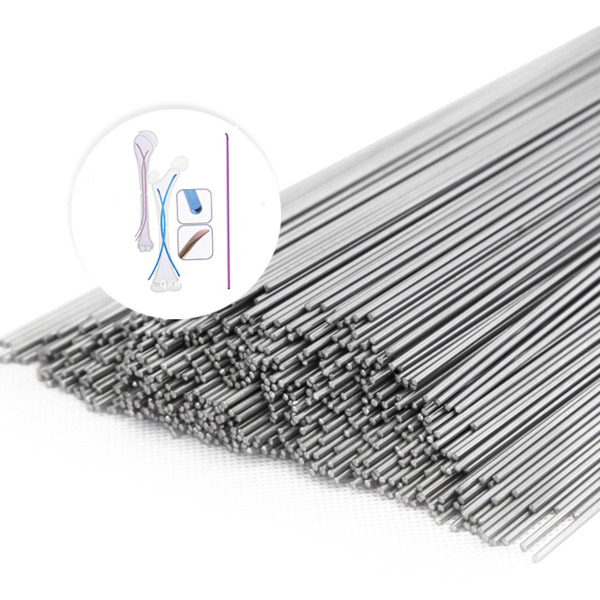

| Application | Kirschner wire, elastic intramedullary nail |

| Certificates | Test report, Third party test report |

2.Chemical compositions

| Grade | Ti |

Chemical composition |

||||||

| Major composition | Impurity(=<%) | |||||||

| Al | V | Fe | C | N | H | O | ||

| Ti-6Al-4V ELI | Bal | 5.5-6.5 | 3.5-4.5 | 0.25 | 0.08 | 0.05 | 0.012 | 0.13 |

| Gr5 | Bal | 5.5-6.75 | 3.5-4.5 | 0.3 | 0.08 | 0.05 | 0.015 | 0.2 |

3. Mechanical property

|

Material |

Status |

Diameter |

Tensile strength (Rm/Mpa) |

Provision of non-Proportional extension strength (Rp0.2/MPa) |

Elongation A/% |

Reduction of area Z/% |

|

Ti-6Al-4V ELI |

M |

1~4mm |

≥860 |

≥795 |

≥10 |

/ |

|

Gr5 |

M |

1~4mm |

≥860 |

≥780 |

≥10 |

/ |

4. Usage of the medical titanium wire

High tensile strength titanium alloy wire is used for Kirschner wire(K wire), which is used in the fixation of bone fractures, bone reconstruction, and as guide pins for insertion of other implant. It is with high ductility.

This product is researched by our company as per customer and market needs 10 years ago, and the usage feedback is good. We have the mature production technique on it.

5.The reason why you choose our company

1) Control the goods’ quality from the beginning to every production process, use grade 0 titanium sponge, melt titanium ingot by imported German ALD vacuum melting furnace.

2) R&D department is supporting on customers’ higher requirements and new material need.

3) ISO 13485, ISO 9001 and AS 9100D certified

4) We have 5 drawing machines and 2 cold drawing machine to produce the wire

5) 100% traceable and supply the test report

6) Good after sales service

For more information of our goods or our company, please feel free to contact us.