008615129504491

|

Most used grades are |

Gr5(Ti-6Al-4V), Gr23(Ti-6Al-4V ELI), Ti-6Al-7Nb |

|

Standard |

ASTM F136, ISO 5832-3, ASTM F1295/ISO 5832-11 |

|

Diameter |

3-100mm |

|

Tolerance |

h7, h8, h9 |

|

Surface |

Polished |

|

Straightness |

Within 1.5‰ |

|

Characteristic |

We can do your high performance customized products |

|

Chemical compositions |

||||||||

|

Grade |

Ti |

Al |

V |

Fe, max |

C, max |

N, max |

H, max |

O, max |

|

Ti-6Al-4V ELI |

Bal |

5.5~6.5 |

3.5~4.5 |

0.25 |

0.08 |

0.05 |

0.012 |

0.13 |

|

Grade 5 (Ti-6Al-4V) |

Bal |

5.5~6.75 |

3.5~4.5 |

0.3 |

0.08 |

0.05 |

0.015 |

0.2 |

|

Ti-6Al-7Nb |

Bal |

5.5~6.5 |

Nb: 6.5~7.5 |

0.25 |

0.08 |

0.05 |

0.009 |

0.2 |

|

Mechanical properties |

|||||

|

Grade |

Condition |

Tensile Strength (Rm/Mpa) ≥ |

Yield Strength (Rp0.2/Mpa) ≥ |

Elongation (A%) ≥ |

Reduction of Area (Z%) ≥ |

|

Ti-6Al-4V ELI |

M |

860 |

795 |

10 |

25 |

|

Grade 5 (Ti-6Al-4V) |

M |

860 |

780 |

10 |

/ |

|

Ti-6Al-7Nb |

M |

900 |

800 |

10 |

25 |

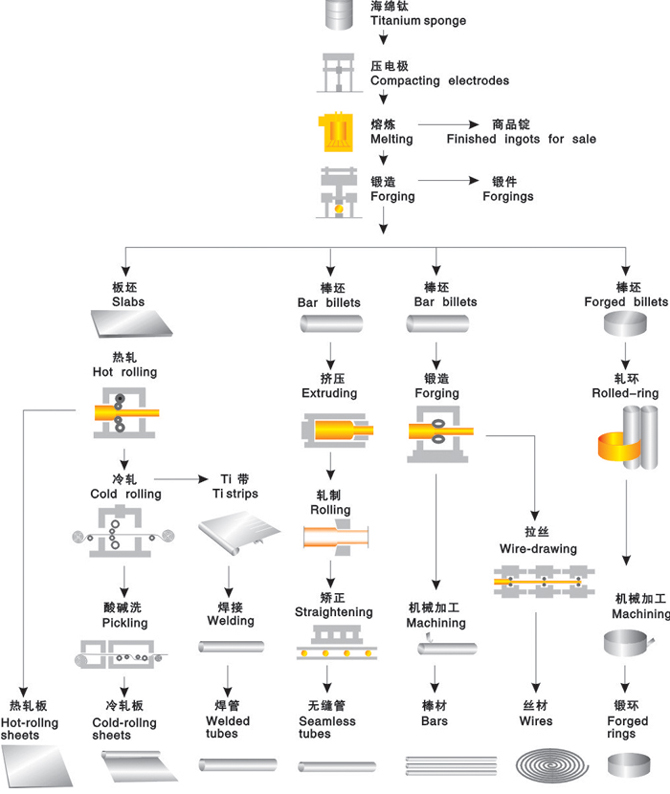

XINNUO imported German ALD Vacuum Oven to melt the titanium ingot by self since 2016, melt 3 times to ensure the chemical compositions’ even, and marking the heat number from titanium ingot to every later production processes, printing it on the final polished bars for later tracking.

With every batch of goods, we test the tensile strength by our Tension Tester and also take sample to the third party lab, supply Mill Test Certificate to customers.

100% ultrasonic flaw detected, heat number and production process are traceable, and XINNUO takes the goods’ quality as the first important thing during the whole production process, will not let the unqualified products delivered out of factory, responsible for every batch of goods supplied.